How to anneal your PET CF parts for better performance

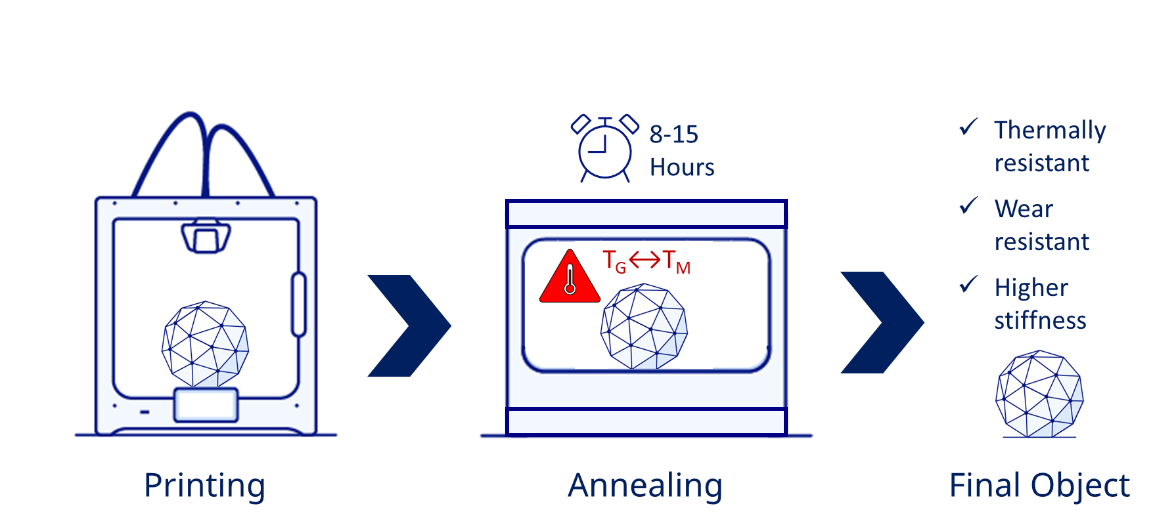

Yet PET CF is also the first material by UltiMaker that is able to be enhanced for even greater performance. That’s because PET CF was designed and tested with annealing in mind. Annealing is a post-processing procedure used to refine 3D printed parts, enhancing their structural integrity and durability. In this guide, we'll explore the benefits of annealing your PET CF parts, and walk you through how to do so.

What is annealing

Annealing is a heat treatment process traditionally used in metallurgy and glassmaking to relieve stresses, increase ductility, and improve material properties. The basic principle involves heating a material to a specific temperature using a specialized oven and then cooling it at a controlled rate.

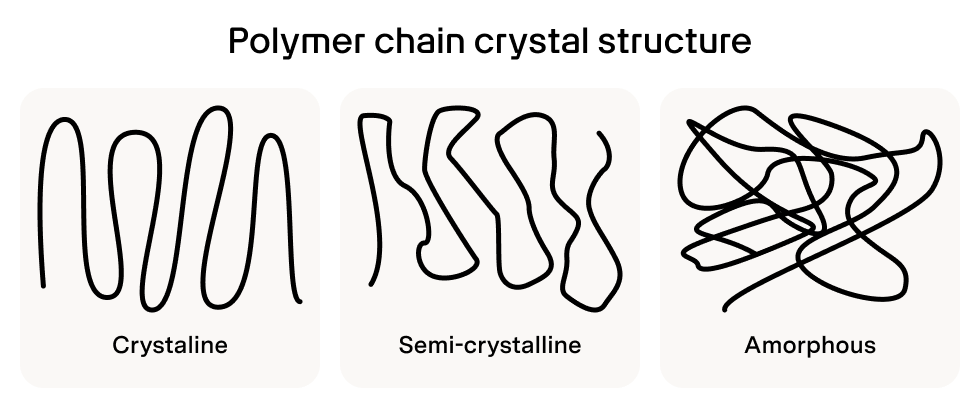

When applied to 3D printed parts, particularly those made from semi-crystalline materials like PET CF and Nylon, annealing can improve mechanical properties such as tensile strength, stiffness, and heat resistance. The results of annealing will vary depending on the material used. For this reason, the process can be complicated and may yield unexpected results. UltiMaker PET CF, however, was designed specifically with annealing in mind.

Why should you anneal UltiMaker PET CF?

PET CF is especially suited to annealing due to its semi-crystalline structure. Many 3D printing polymers such as ABS and PETG have an amorphous structure which means the polymer chains within them are arranged in a chaotic way. Similar to a bowl of spaghetti on a molecular scale. Crystalline structures are made up of ordered chains that result in better strength properties. A semi-crystalline material like PET CF can be crystalized by heating it to its glass transition point so that the polymer chains within it become more organized, and therefore stronger.

The suitability of PET CF, combined with the extensive testing and validation that we performed while developing it, makes it the perfect candidate for annealing. If you follow the guidelines in this article, you will end up with a part that is stronger, stiffer, and more heat-resistant.

Based on those numbers, you can expect the following performance increases:

- A strength increase of 30%

- A stiffness increase of 10%

- An increase in heat resistance from 80 °C to 180 °C

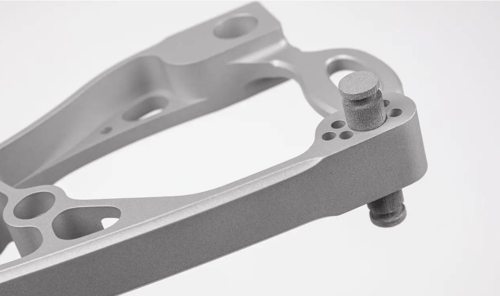

These improvements are huge and make PET CF a viable replacement for metal and carbon fiber parts created using costly traditional manufacturing techniques.

Before we explain how you can realize these impressive improvements, let's talk quickly about the downsides of annealing your parts and in which situations you may want to avoid doing so.

The downsides of annealing your part

Firstly, your part will shrink slightly when it is annealed. This is one of the reasons why the process is so complicated. It’s also possible for your part to warp or sag while being heated. Luckily, however, we can compensate for both of these issues. We will explain how during the next section of this blog.

The second and more impactful downside is that there will be a reduction in some of the specific mechanical properties of your part. Particularly, impact resistance and Z-adhesion resistance. Your part will be less resistant to pressures perpendicular to the orientation in which it was printed. You can expect a decrease of tensile strength in the Z-axis of around 15%. For this reason, it’s important to carefully consider how your part is oriented during printing so that your final part is not weakened in the direction in which force will be applied to it.

How to anneal PET CF

To ensure success when annealing your part, you need to consider the requirements of annealing at every step. That starts with selecting (or designing) your 3D model. The annealing process does not work well on models with thin walls. For best results you should avoid walls of less than 4 mm thickness and try to adhere to part design best practices.

Next, when slicing your part, you need to compensate for the shrinking process. For PET CF, the shrinkage experienced during annealing is - 0.3% in the XY axis’ and - 1.7% in the Z axis. You can compensate for this manually by enlarging your part but that is not necessary when using UltiMaker Cura. Instead, you can choose the professionally tailored annealing intent profile and it will apply the relevant compensations automatically.

Finally, you need to make sure that supports are used if your part has any significant overhangs or bridges. This is because these features can sag during the annealing process. You can choose to use either regular supports (support structures printed with PET CF) or multi-material supports using the UltiMaker Breakaway support material.

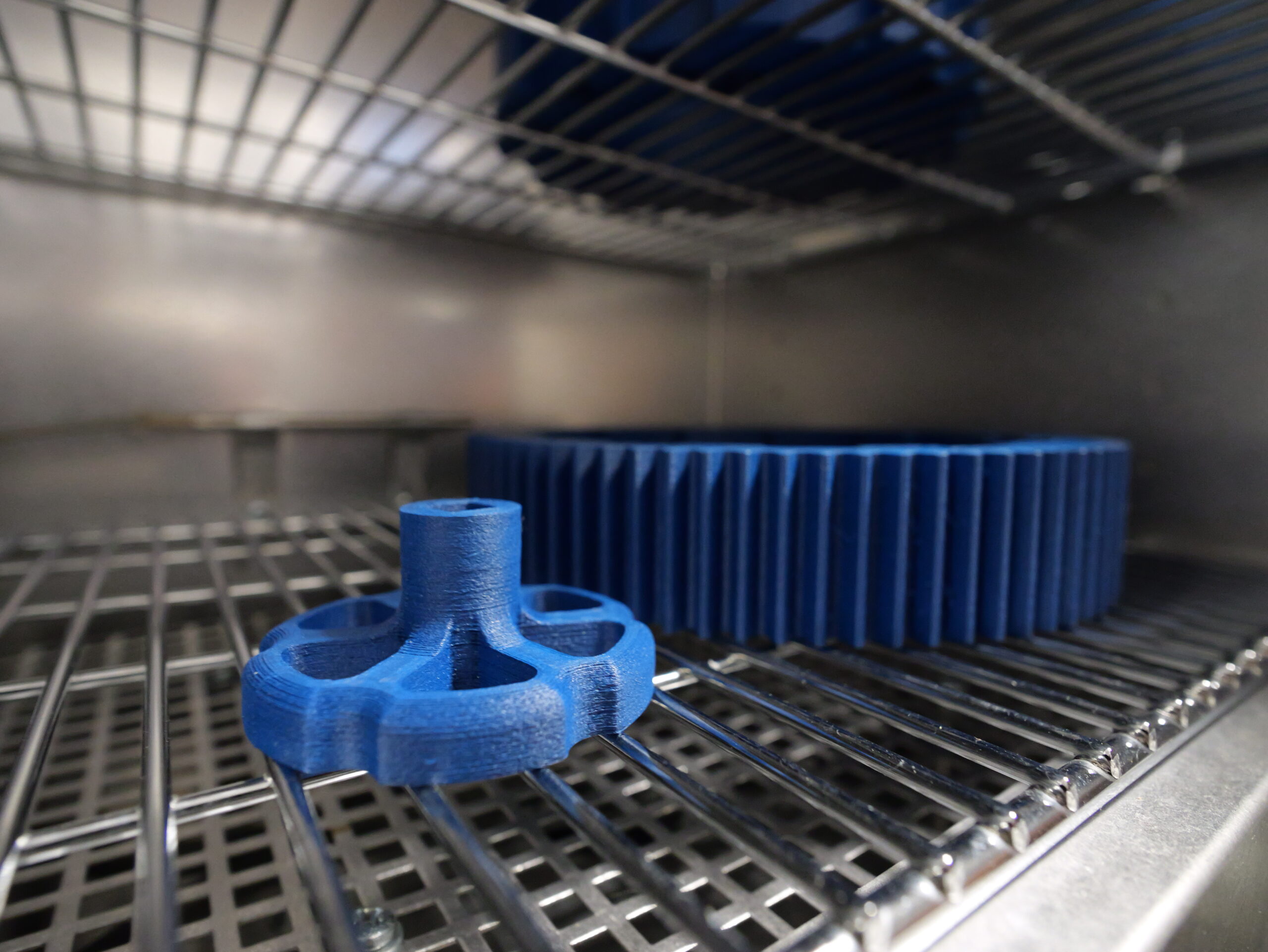

Once you have selected the annealing profile, you can slice and print your part. When removing your part from the printer, do not take it off the build plate. This is because the part needs to be annealed in the same orientation in which it was printed. Putting the print in the annealing oven still attached to the build plate is an easy way to ensure this while making sure that any supports remain in place. Both flex plates and glass plates can be used in an annealing oven.

Now, it’s time to operate your annealing oven. Any oven designed for annealing can be used but we recommend a high-quality professional machine.

Programming your oven

Before turning on your oven we need to determine how long it should be annealed for. You can do this by measuring the thickest section of your part. The annealing time in hours is the thickness in mm / 2. Let's say your part is 4 mm thick, then you would need to anneal the part for 2 hours at the annealing temperature. The specifics of programming your annealing oven should be provided in the user manual for your oven.

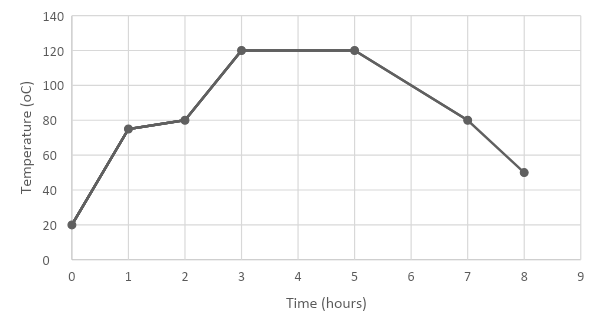

A verified annealing profile for a PET CF sample of 4 mm thickness is depicted below. Different annealing temperatures (Tc) can be decided upon based on property preferences. Higher temperatures will result in a part with higher thermal resistance but lower stiffness and increased shrinkage. It is advised to maintain heating/cooling ramps for optimal results. High-temperature annealing will therefore result in longer annealing times.

| Process | Duration (h) | Temp (°C) | Ramp (°C/h) |

|---|---|---|---|

| Start | (N/A) | 20 | (N/A) |

| Heat to Tg | 1 | 75 | 55 |

| Unstress | 1 | 80 | 5 |

| Heat to Tg | 1 | 120 | 40 |

| Anneal | 2 | 120 | (N/A) |

| Cool to Tg | 2 | 80 | - 20 |

| Cool to RT | 1 | 50 | - 30 |

| Total | 8 |

Once the object is cooled down and retrieved from the oven, the annealing process is completed, and the part is ready for use. Regular post-processing methods like sanding, polishing, and coating can be applied if desired.

Recap of the annealing process

Here is a quick recap of all the steps needed to anneal your part:

- Select an appropriate part (no thin walls)

- Orient your part correctly in Cura taking into account Z-axis resistance

- Select the annealing intent profile

- Use supports if necessary

- Slice and print your part

- Measure your part to determine the annealing time

- Insert your part into the annealing oven in the same orientation in which it was printed

- Remove your annealed part from the oven and post-process if necessary

We hope this guide helps you get the most out of your materials. Annealing can seem like a confusing process but UltiMaker PET CF makes it easier than ever! If you have any questions, please don't hestitate to contact our 3D printing experts.

Wil je nooit onze blogs missen?

/dennie-rijk-spreker-layertec.jpg?width=80&height=80&name=dennie-rijk-spreker-layertec.jpg)

/dennie-rijk-spreker-layertec.jpg)

-1.png?width=300&height=225&name=whitepaper%20-%20virtual%20twins%20(1)-1.png)